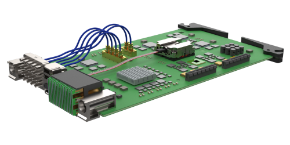

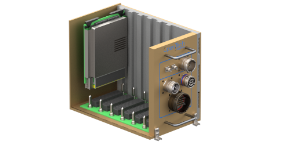

In the realm of high-performance embedded computing, VITA 46 (VPX) standards have revolutionized how systems are designed and integrated, particularly in demanding environments like aerospace and defense. Guide hardware is a critical component of these systems, ensuring proper alignment and secure connections. This blog post explores the key aspects of VITA 46 guide hardware and what to consider when selecting the right components for your applications.

VITA 46 Guide Hardware

VITA 46, commonly known as VPX, is a set of standards that define high-speed interconnects and robust mechanical structures for embedded systems. Guide hardware, including guide pins, bushings, and alignment keys, plays a vital role in maintaining the integrity and reliability of these systems by ensuring precise module alignment and secure connections.

Key Considerations for Selecting VITA 46 Guide Hardware

When choosing guide hardware for VITA 46 systems, several factors need to be considered to ensure optimal performance and reliability. Here are the essential aspects to keep in mind:

Compatibility with VPX Standards

- Ensure that the guide hardware you select is fully compliant with VITA 46 standards. This guarantees compatibility with other VPX components and ensures the system meets industry benchmarks for performance and reliability.

Material and Durability

- The material of the guide hardware significantly impacts its durability and performance. Common materials include stainless steel, aluminum, and high-strength polymers. Choose materials that can withstand the specific environmental conditions your application will face, such as high temperatures, vibration, and corrosive environments.

Precision and Tolerances

- Precision in manufacturing is crucial for guide hardware to ensure accurate alignment and secure connections. Check the tolerances specified by the manufacturer to ensure they meet the stringent requirements of your VPX system. High precision reduces the risk of misalignment, which can lead to system failures.

Environmental Resistance

- For aerospace and military applications, the guide hardware must be resistant to environmental factors such as moisture, dust, and chemicals. Look for components that are rated for the specific conditions your system will encounter, ensuring long-term reliability and performance.

Ease of Installation and Maintenance

- Consider guide hardware that is easy to install and maintain. Features like self-aligning capabilities and modular designs can simplify the installation process and reduce maintenance time, ensuring that your system remains operational with minimal downtime.

Mechanical Strength

- The mechanical strength of the guide hardware is essential for maintaining the integrity of the connections in high-stress environments. Ensure that the selected components can handle the mechanical loads and stresses they will encounter during operation.

Cost-Effectiveness

- While it is crucial to select high-quality guide hardware, cost considerations also play a role. Balance the need for durability and performance with budget constraints to find a solution that offers the best value for money without compromising on essential features.

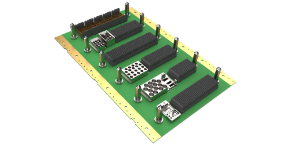

Common Types of VITA 46 Guide Hardware

Understanding the different types of guide hardware available can help you make an informed selection:

Guide Pins and Bushings

- These components ensure precise alignment of modules during installation. High-quality guide pins and bushings reduce the risk of misalignment and ensure secure connections.

Alignment Keys

- Alignment keys are used to ensure proper orientation and prevent incorrect insertion of modules. They are crucial for maintaining the integrity of the system and preventing damage during module installation.

Card Locking Mechanisms

- These mechanisms secure the modules in place, preventing movement and ensuring a stable connection. They are essential for systems that operate in high-vibration environments.

Conclusion

Selecting the right guide hardware for your VITA 46 (VPX) system is critical for ensuring reliable performance and longevity. By considering factors such as compatibility, material durability, precision, environmental resistance, ease of installation, mechanical strength, and cost-effectiveness, you can make an informed choice that meets your system's specific needs. With the right guide hardware, your VPX system will be well-equipped to handle the demands of modern aerospace and defense applications, ensuring robust and reliable performance.

For more information on VITA 46 guide hardware and other embedded system components, visit Open.Tech.